Classification and characteristics of laminating machines

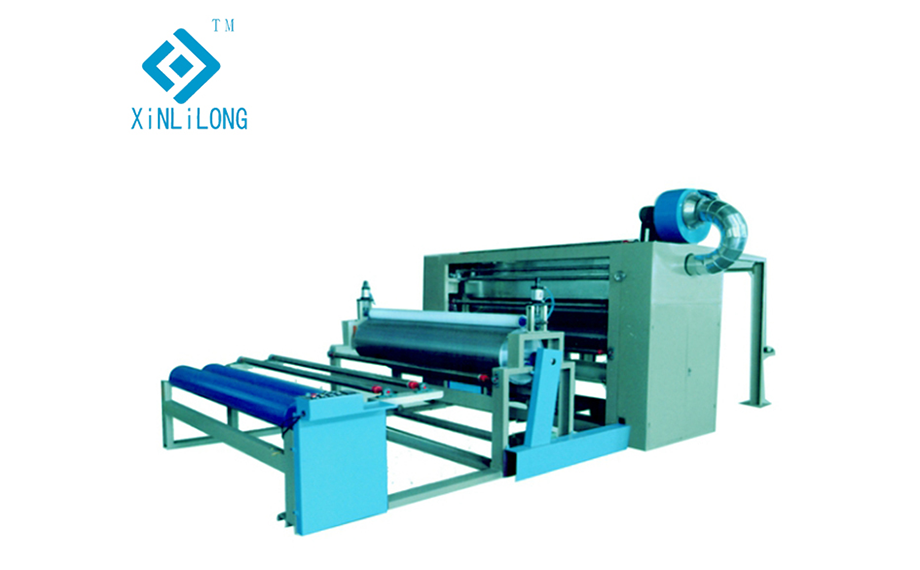

What is the laminating machine

Laminating machine, also known as bonding machine, bonding machine, is to heat two or more layers of the same or different materials (such as cloth, paper, artificial leather, various plastics, rubber sheet coils, etc.) to dissolve, semi-dissolve state or mechanical equipment compounded with special adhesives.

Classification of laminating machines

- 1.Flame type: suitable for laminating of sponge and other textiles and non-woven products. It is used in flame retardant sponge as bonding material without glue. It is dissolved and bonded by flame spray, especially suitable for the bonding of plush and deerskin, and has the characteristics of environmental protection, good hand feeling and wash-ability.

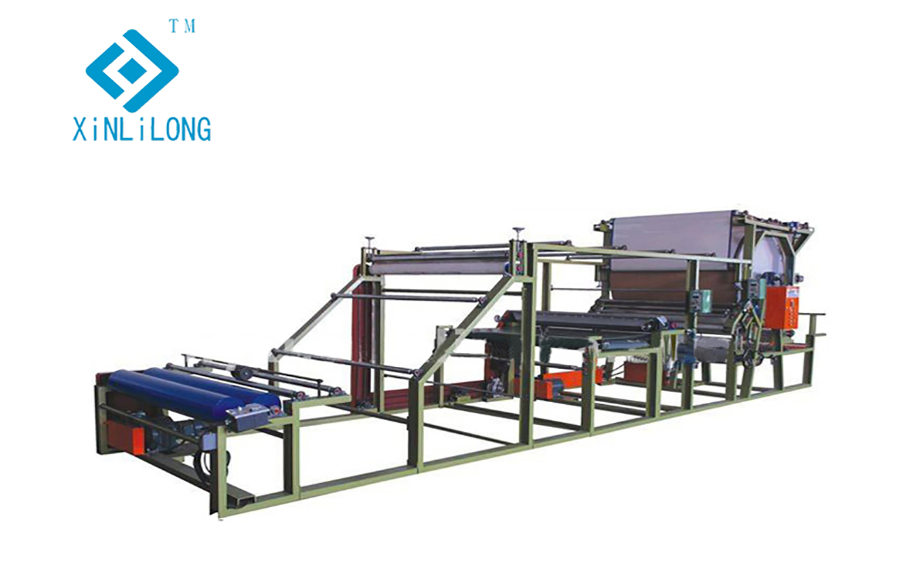

- 2.Mesh belt type: This machine is suitable for sizing and laminating of sponge, cloth, EVA, artificial leather and non-woven fabrics. It is pressed with high temperature resistant mesh belt, which improves the smoothness of the fit and the adhesion of the product, while occupying less space. The machine adopts frequency conversion synchronous control to realize the synchronization of the composite main drying cylinder and the composite winding, which is more convenient to use.

- 3.Double glue type: This machine is suitable for gluing and laminating the surface of fabrics, non-woven fabrics, sponges and other fabrics. With double pulp tank, two layers of fabric can be coated at the same time to improve the bonding fastness.

- 4.Glue point transfer type: This machine is suitable for laminating between textiles, non-textiles, breathable films and other fabrics. Transfer the glue evenly to the lining cloth or film, and then compound with the top cloth.

5.Glue spray type: This machine is suitable for the compounding of textiles, non-textiles and other fabrics. The glue is evenly transferred to the lining cloth by spraying method, and then compounded with the surface cloth.

Features of the laminating machine

1. Two layers of materials can be glued together at the same time to make the composite fastness better. It can also be used to paste three layers of thin materials at one time to improve production efficiency and reduce production costs.

2. The double-groove mesh belt is compounded and pressed with a high temperature resistant mesh belt to make the compound material fully contact with the dryer, improve the drying effect, and make the processed material soft, washable and fast.

3. The mesh of this machine is equipped with an automatic infrared deviation adjustment device, which can effectively prevent the mesh belt from deviating and prolong the service life of the mesh belt.

4. The heating system of this machine is divided into two groups. Users can choose the heating method (one group or two groups) according to their needs, which can effectively save energy and reduce production costs.

5. Select DC motor or inverter linkage according to needs, so that the machine has better control effect.